SinLog

a complete, clear and versatile software/hardware system

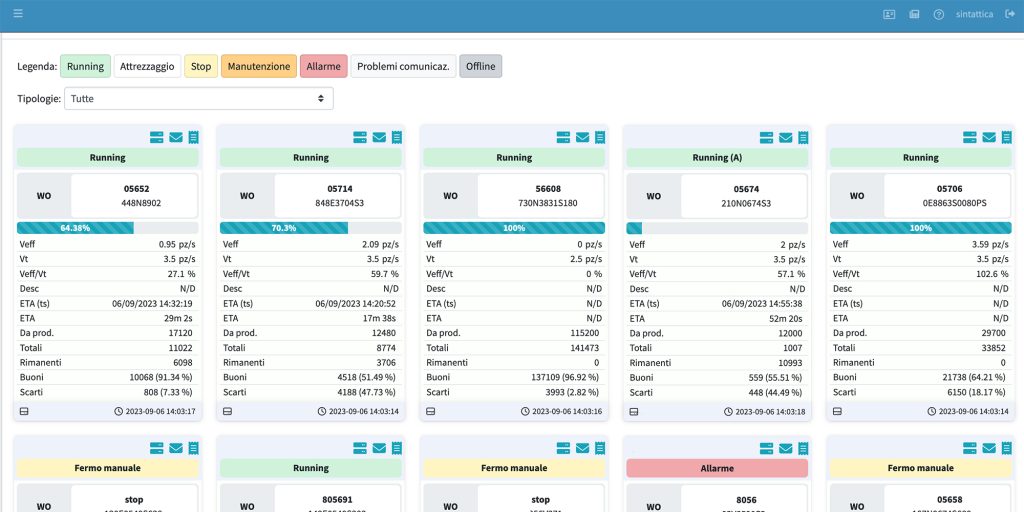

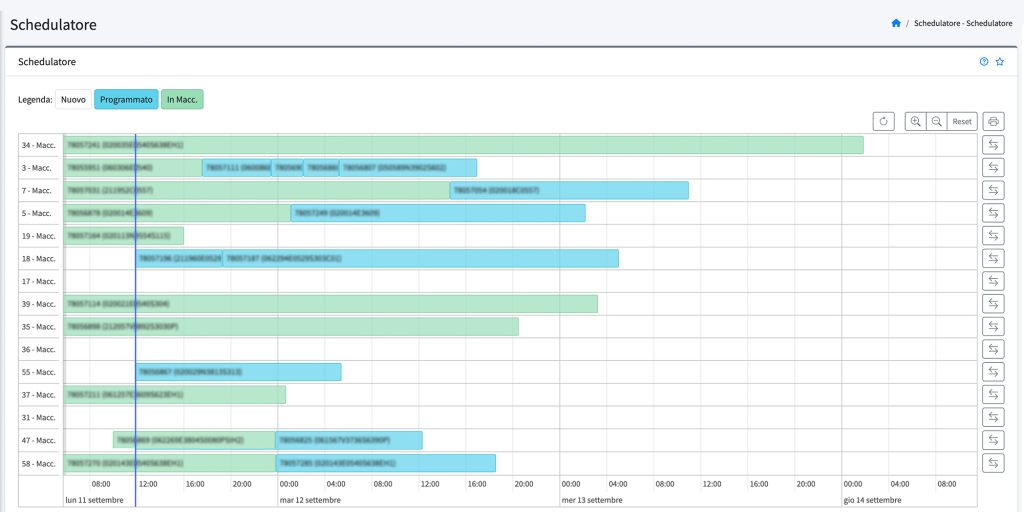

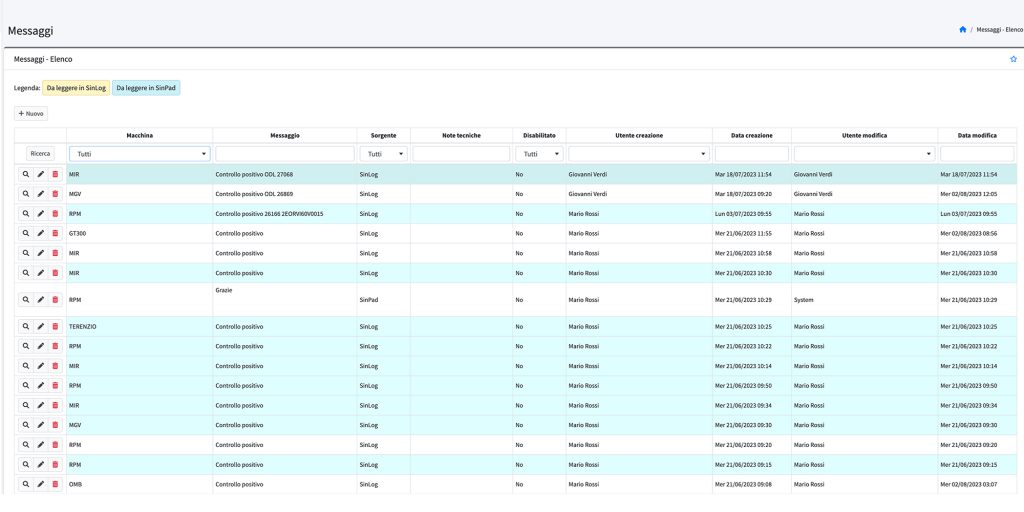

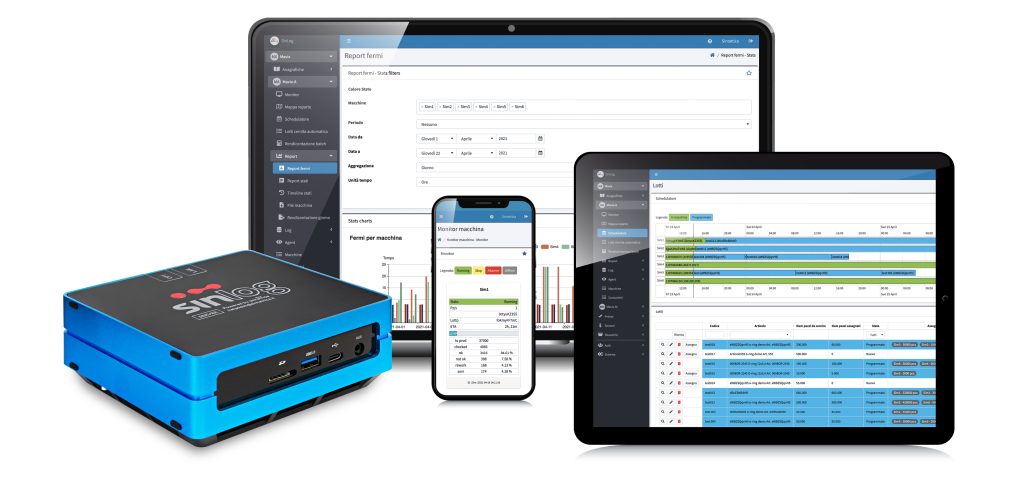

SinLog Desktop is the core of the system. Installed on a local server, it allows all components to communicate, coordinating data and information from different sources: operators, machines, ERP.

The desktop program has connectors for exchanging data to and from any production management software. In the absence of an ERP software, SinLog works in stand alone mode with its own records.

SinLog can be accessed with a web browser from any device (PC, tablet, smartphone). No specific hardware is required.

SinLog is multi-user and multi-profile. Each user has their own credentials and is profiled to access data and functions dedicated to them. There is no limit on the number of users.

REMOTE ACCESS

Being web based, SinLog is the ideal tool to monitor production remotely, with a standard internet connection.

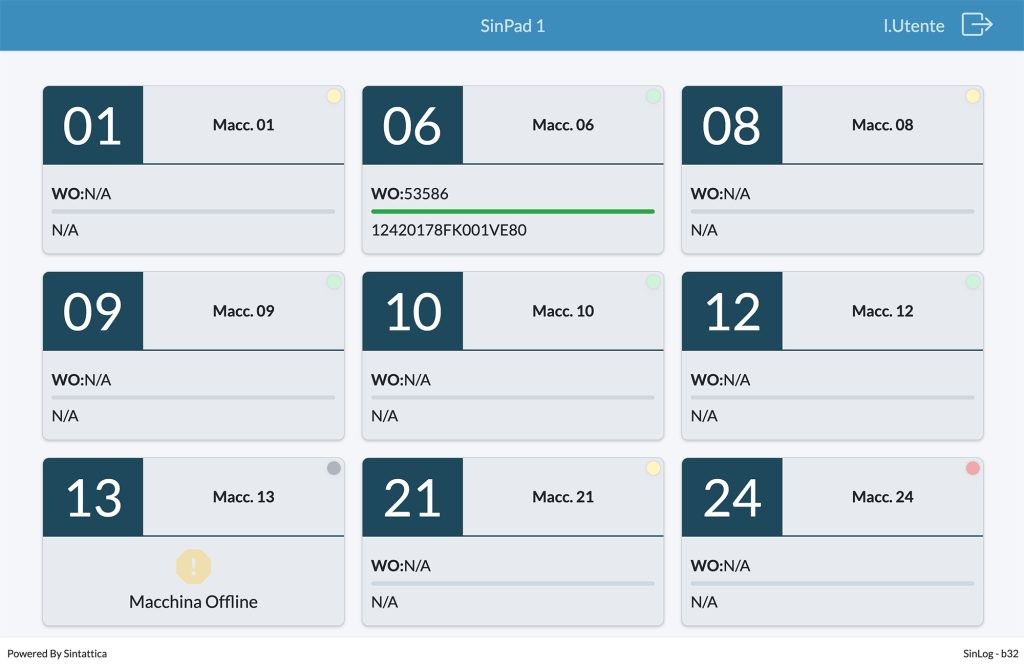

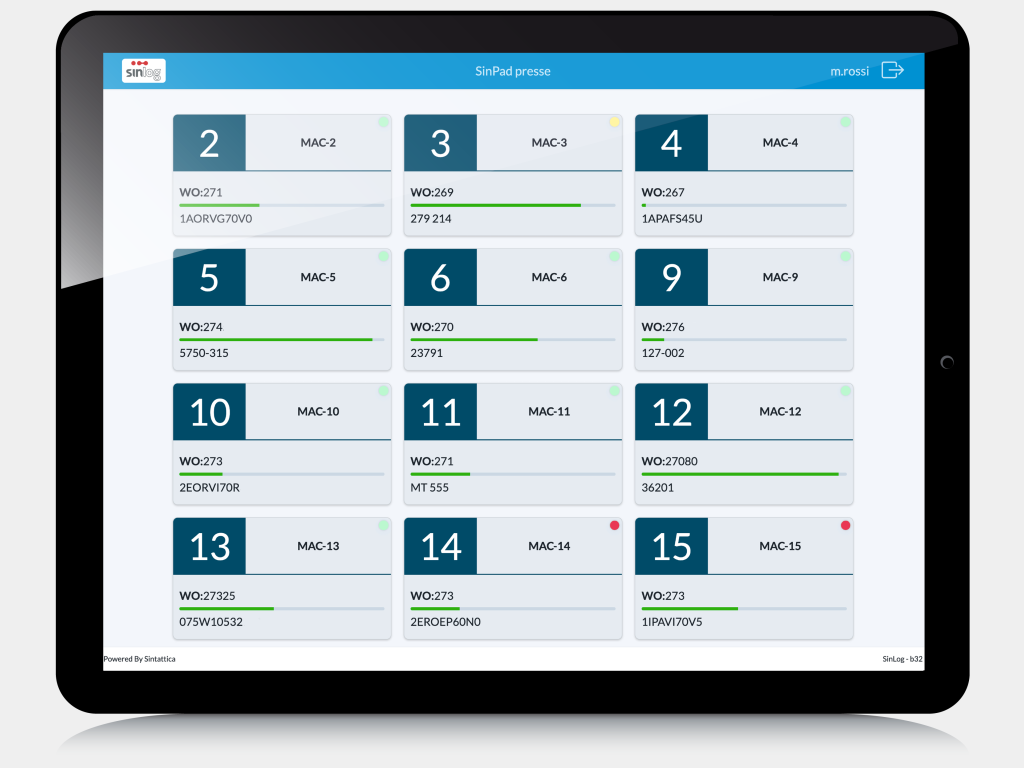

SinPad

web app for managers and department operators

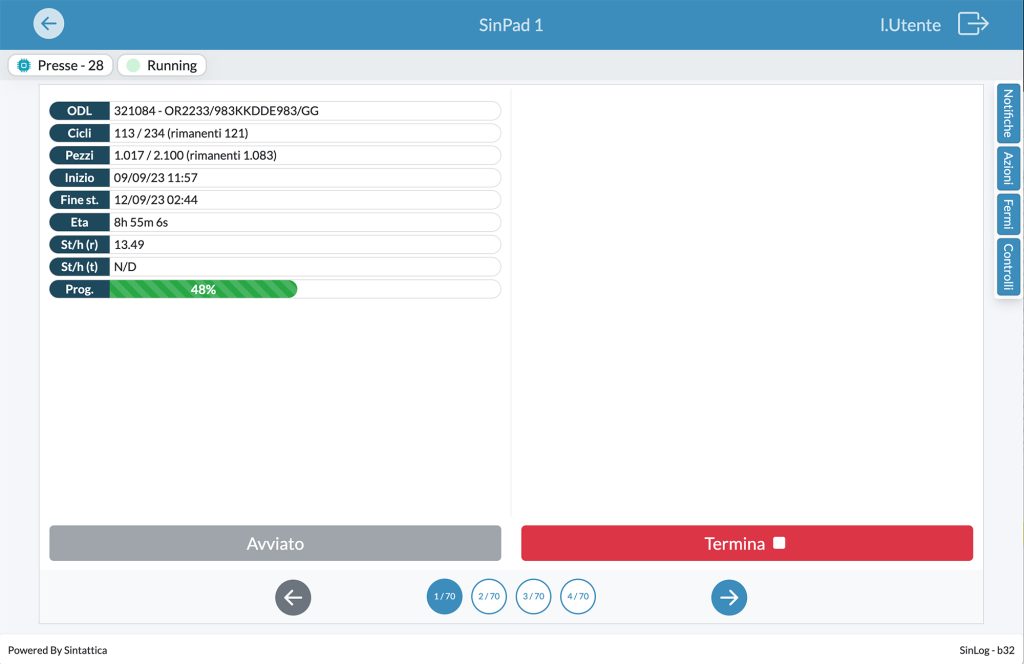

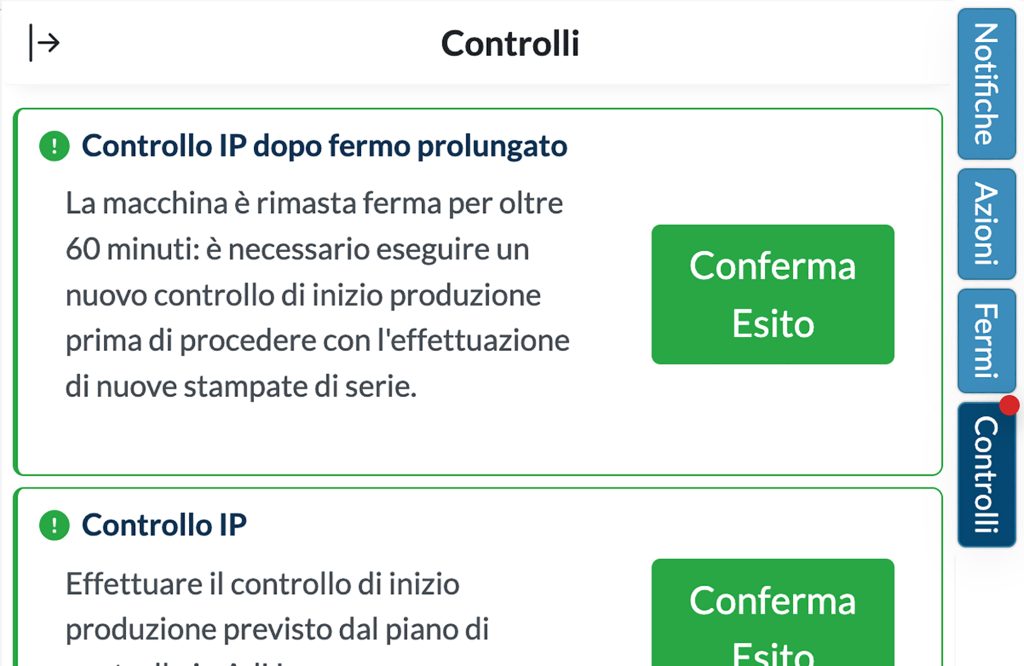

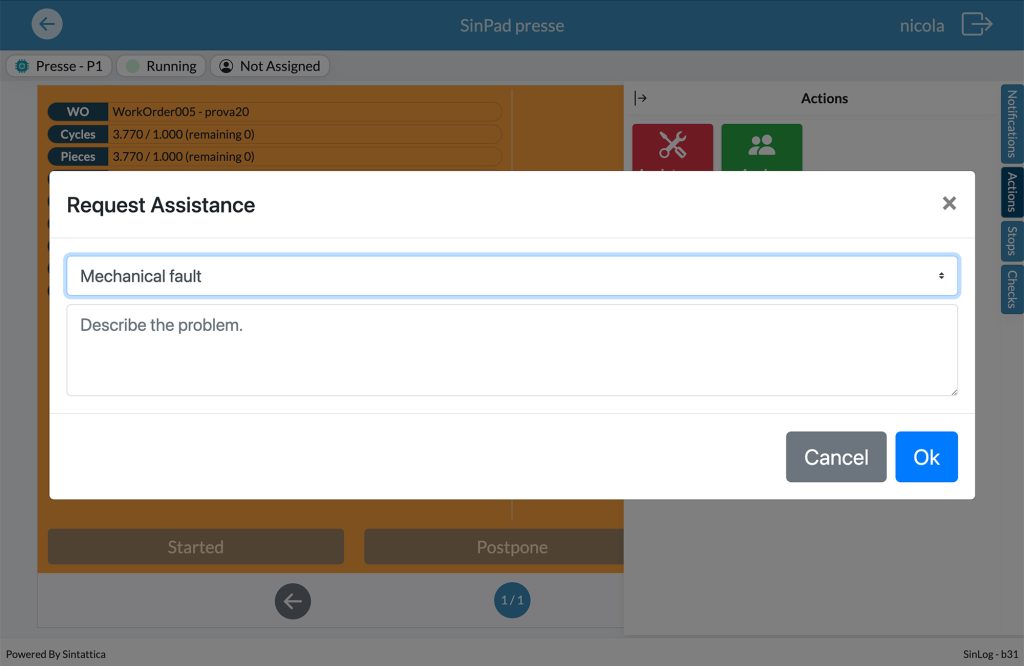

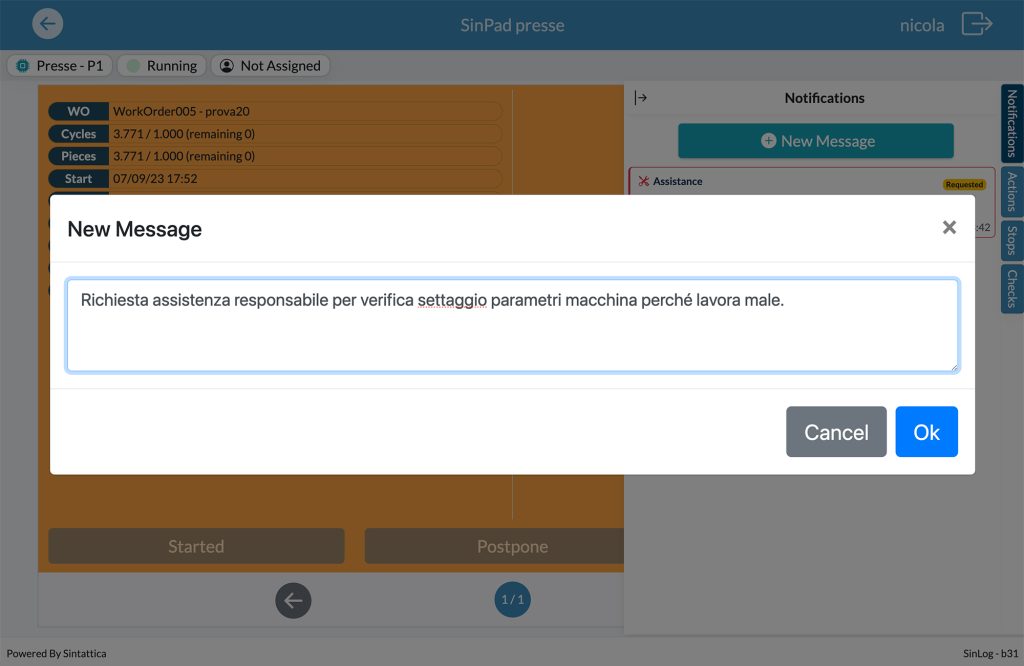

SinLog is supplied with the SinPad application, dedicated to department operators.

Through a simple and intuitive interface, SinPad allows operators to see the which batch should be produced, declare the start and end of the process, read messages and instructions to carry out their work in the best possible way.

SinPad can be used on any mobile device equipped with a browser, both tablets and smartphones.

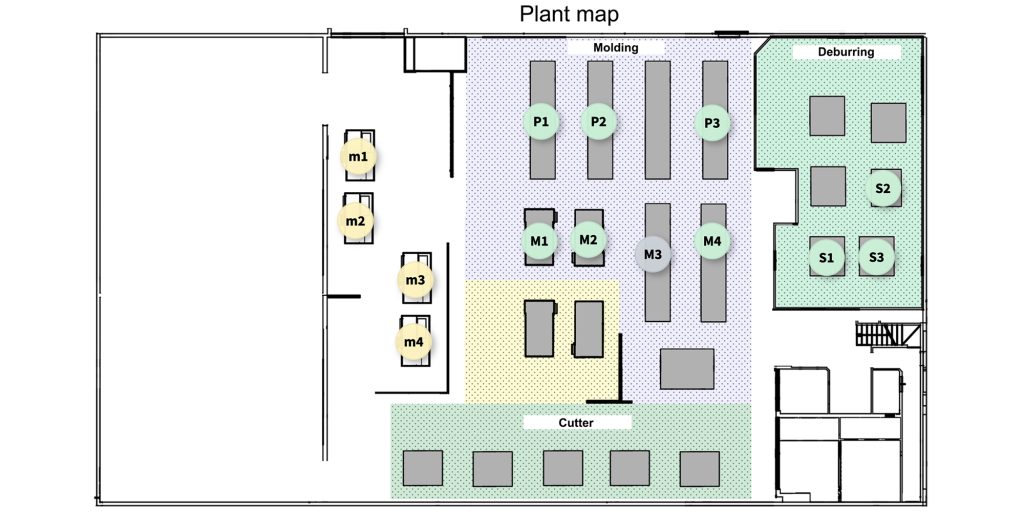

SinBox Edge

the hardware device for collecting data from the machines

SinLog can connect directly to the PLC of each machine to be monitored or, for older machines, use the SinBox Edge hardware device. Collected data is sent in real time to the server which shows them on the monitor, updates the planner and evaluates the efficiency of the system.

SinBox Edge is easily installed. It picks up electrical signals and communicates via WiFi with SinLog server. It can be placed inside or outside of the machine, depending on availability.

DETECTION OF ALARM SIGNALS

SinBox Edge detects and transmits machining, stopped, alarm signals and more. It can also be connected to a counting pulse to measure the production rate

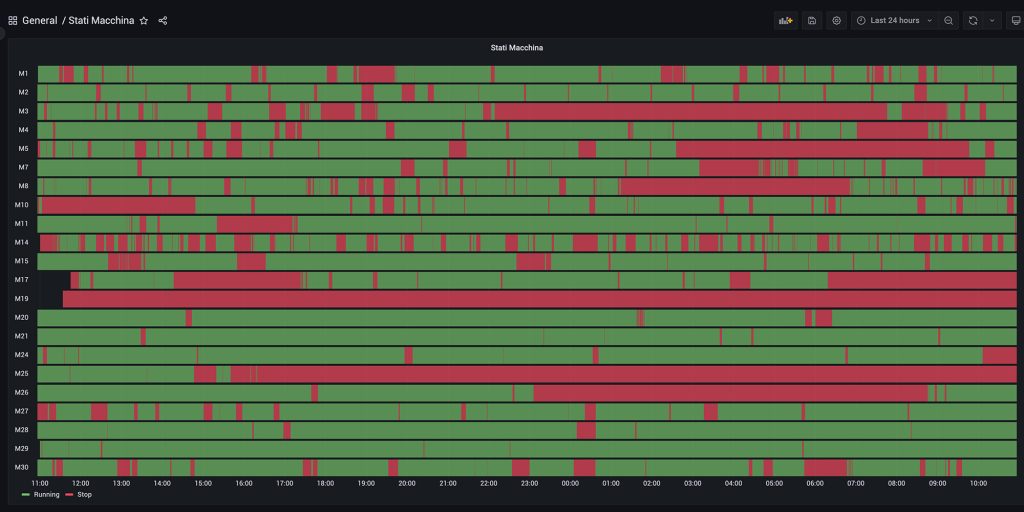

MACHINE STATUS MONITORING

A machine stopped due to an anomaly is immediately detected and reported to SinLog. This allows for rapid intervention which could otherwise take place after hours of inactivity

COUNTING OF PIECES/CYCLES

The integrated counter allows constant measurement of both the number of pieces produced (or cycles performed) and the time elapsed, in order to always have a comparison between the real measured data and the theoretical data

Graphs and dashboards

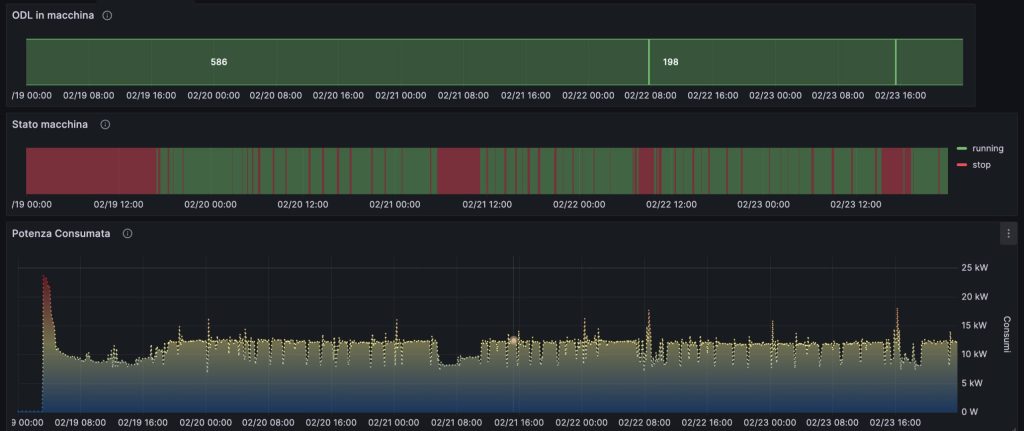

SinLog can be integrated with Grafana, a platform for creating dashboards and graphs in real time or based on time series.

The real-time collected data periodically stored in the dedicated database which groups them in time series and presents them as specific graphs.

Represented information is useful for both production control and historical consultation of work phases or machine status

EcoSense

environmental sensor

EcoSense is an additional SinLog module for the collection of environmental data. It’s based on a dedicated multisensor, allowing constant monitoring of the environmental data detected by the hardware device to be located in the department.

The sensor is connected to SinLog server which, at configured time intervals, stores collected data so that it can be shown in the form of graphs.

Data can be consulted from a dedicated dashboard, and is stored in order to guarantee a 12-month history.

SinLog EcoSense offers a tool for constant monitoring of environmental conditions in production departments.

Thanks to the SinLog ecosystem, data can be correlated with production data recorded by machines and operators.

The integrated system thus allows constant control of the situation, checking production and performance trends.

SinLog EcoSense means greater company attention towards the customer. The company that uses EcoSense proves to be attentive to detail, at the forefront of process control and therefore capable of offering high quality standards.

SinLog EcoPlug Detect

Connect, monitor, save: the small analyser that fits on every machine to discover hidden waste.

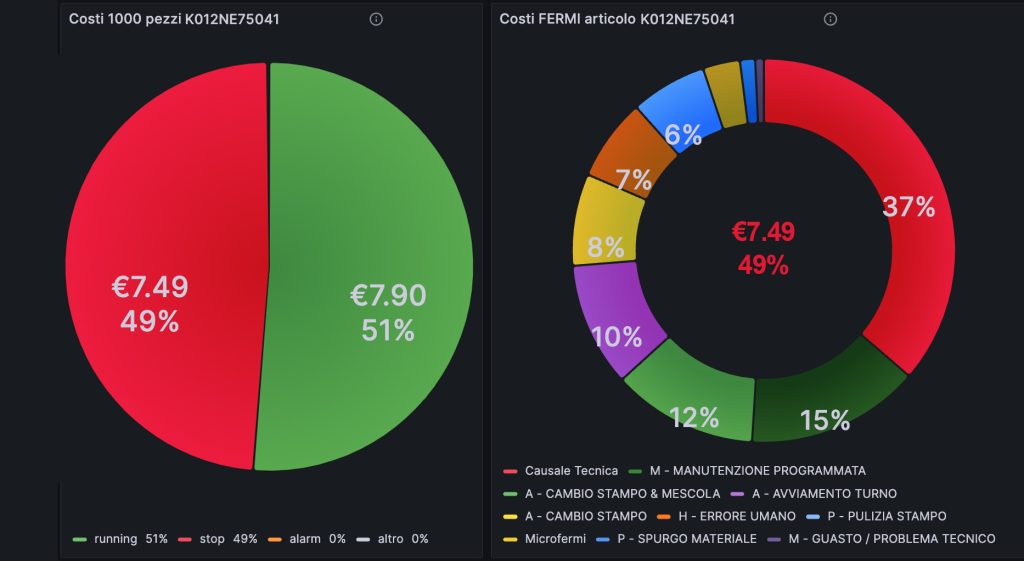

EcoPlug Detect is the combination of a hardware energy-counting device integrated with information from the SinLog software.

Integrated into SinLog, it allows the energy consumption data collected to be associated with production batches and, consequently, with specific articles. This innovative point data collection system is capable of providing detailed and accurate information.

How it works

The device is installed on a DIN rail and connected to the machine phases.

It is then connected to the WiFi network so that data can be sent to the SinLog server.

Service by a maintenance technician takes only a few minutes, while configuration of the device is carried out by Sintattica technicians.

- machine status

- batch in process

- punctual consumption for each moment

- energy consumed for production or downtime

The project, born as SINLOG IEE and now named EcoPlug Detect, is an initiative funded by the Lombardy Region through the European Regional Development Fund to transform the energy sector through digital innovation in full adherence to the Transition 5.0 Plan